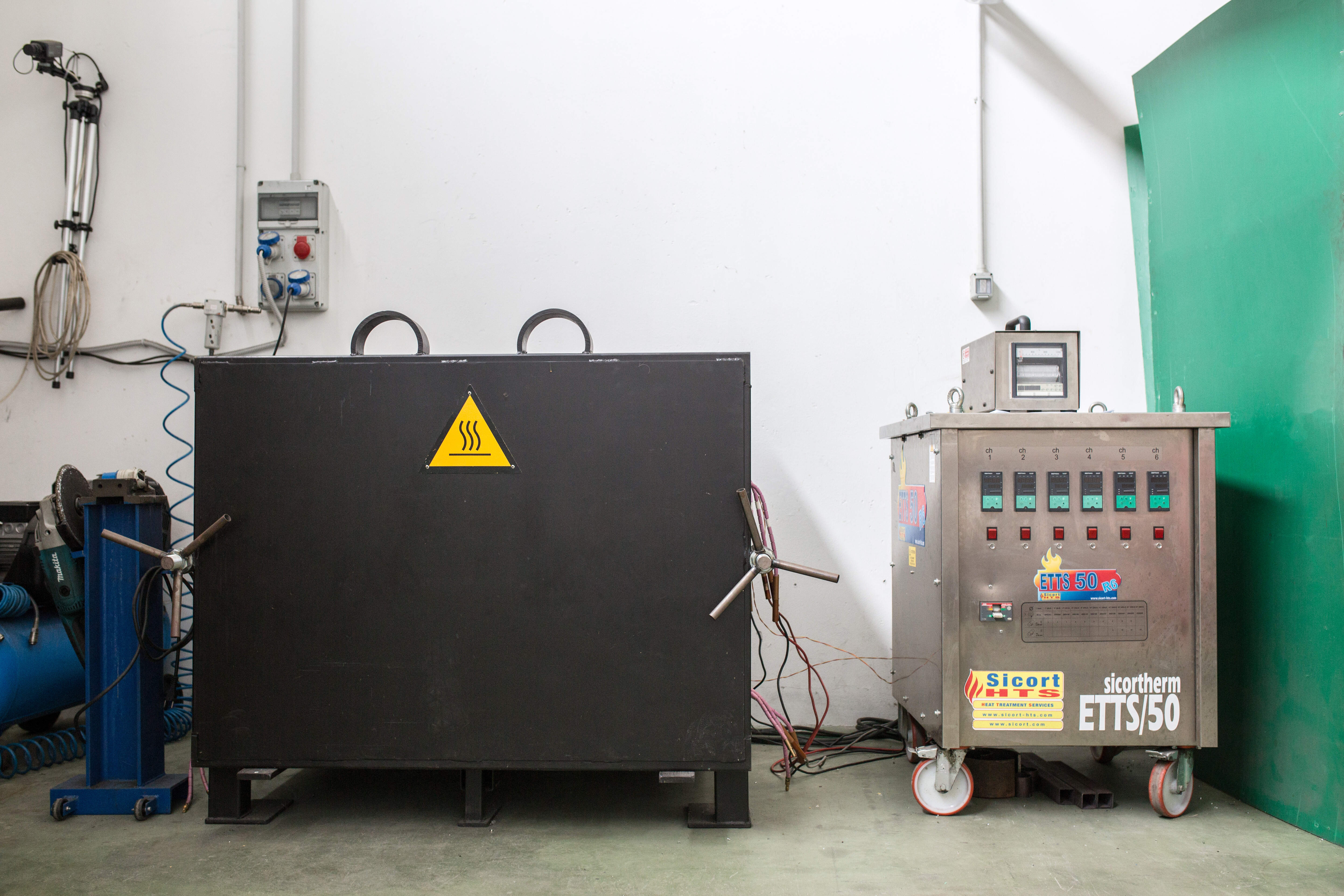

Our electric furnace enables us to perform thermal treatments, by simulating the same characteristics and conditions as those that will be performed during the production cycle.

When required at the end of a production cycle, the heat treatment has to be carried out even before conducting tests on materials and welds, in order to verify the actual mechanical properties at the end of production.

Our electric furnace is connected to the computer system and it is entirely controlled by a specific software, which allows to set the heat treatment temperature, the holding time and the ascent and descent gradient.

We can perform aging, stress relieving, step-cooling and normalizing treatments, up to a temperature of 1100° C.

P.I. 01338800384

SdI code: BA6ET11

Via F. Luigi Ferrari 24/C

Ferrara

44122

Italia

Studio V.M. S.r.l. ©